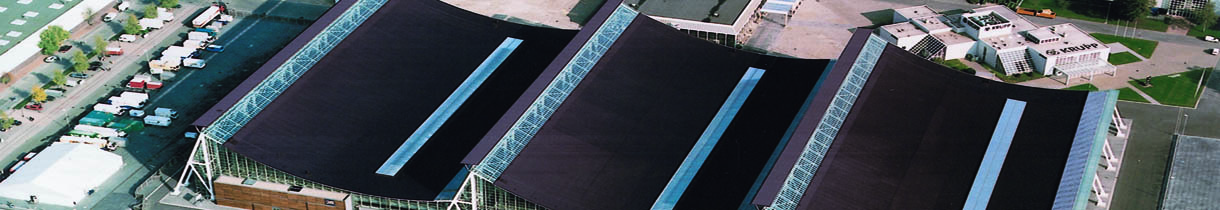

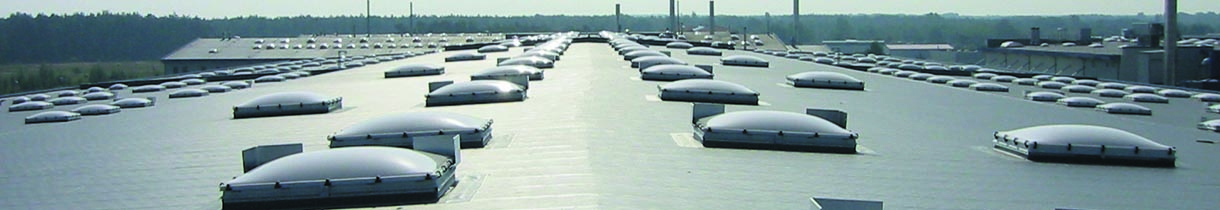

Roofing sheets must be able to withstand high stresses on site

Similar to the spine in the human body, the roofing sheet is stabilized by an intermediate layer of non-woven glass fibres. This structure is the result of innovative extrusion technology. This guaranties that the roofing sheets meet the particularly high requirements for durability. Roofing sheets must be able to withstand high stresses on site and without a safety layer offer high perforation protection, e.g. against hail, snow or subzero temperatures! Material standards do not take into account the demands of the often very rough realities on a building site. Additional information comes from trials (cigarette burns, hard-solder drops

and felt nails). The results established by Ernst confirm the experience we have gathered over the years. A sheet thickness of 2 mm and the inserted glass fibre fleece core reduce the risk of damage during building to a minimum. The same applies to the mechanical / thermal stresses on open air weathering roof areas.

The layer of nonwoven glass fibres ensures excellent flatness and avoids waves and creases being formed during laying.

Lucobit®: Design of a sealing sheet ECB sheets with an intermediate layer of non woven glass fibres are:

and felt nails). The results established by Ernst confirm the experience we have gathered over the years. A sheet thickness of 2 mm and the inserted glass fibre fleece core reduce the risk of damage during building to a minimum. The same applies to the mechanical / thermal stresses on open air weathering roof areas.

The layer of nonwoven glass fibres ensures excellent flatness and avoids waves and creases being formed during laying.

Lucobit®: Design of a sealing sheet ECB sheets with an intermediate layer of non woven glass fibres are:

- tear resistant,

- heat resistant,

- resistant to high spot loads,

- excellent in regard to flatness and dimensional stability,

- simple and safe to weld,

- easy to cut into different shapes,

- easy to lay without direct contact with glass fibres.

LUCOBIT Germany

LUCOBIT Germany  LUCOBIT Group

LUCOBIT Group  LUCOBIT International

LUCOBIT International